Go Back

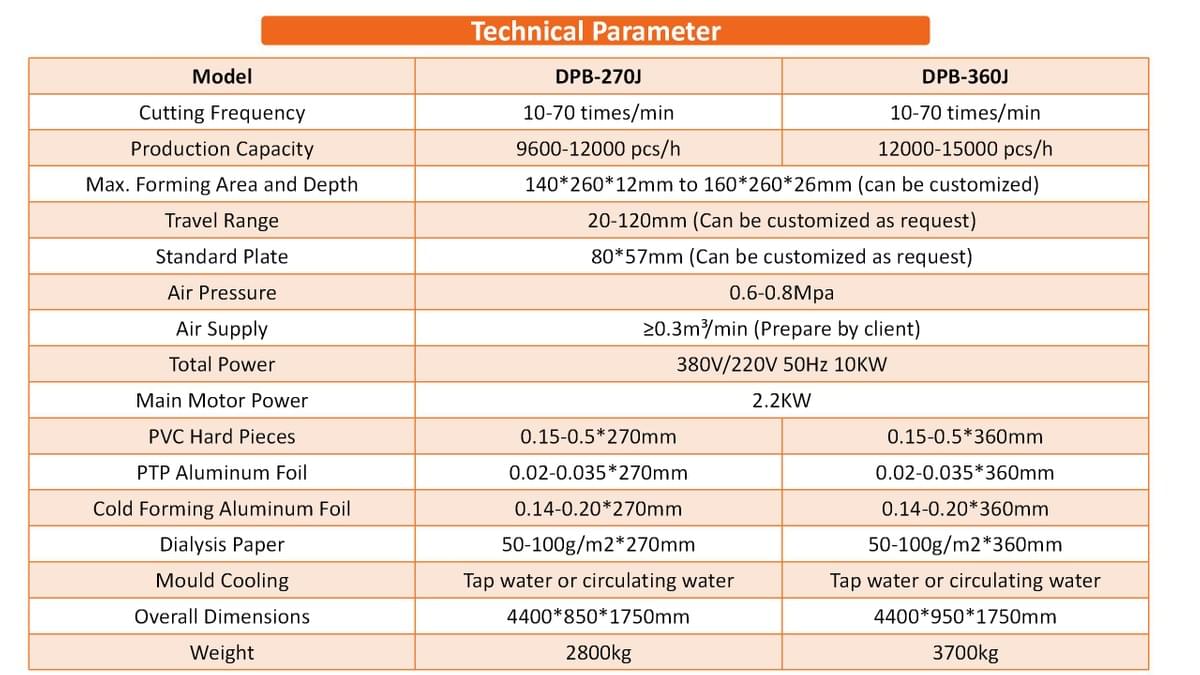

DPB-270/360J Cantilever Style Flat-Plate Blister Packing Machine

This machine is applied to Alu-Pvc and Alu-Alu packing of medicines, various syringes, ampoule bottles and medical products, food, electronic parts, hardware products, etc.

More Details

DPB270J/DPB360J Cantilever Style Flat Plate Blister Packing Machine

Application

- This machine is applied to Alu-Pvc and Alu-Alu packing of medicines, for example sealed blister packing of capsules and tablets of various specifications.

- Applied to sealed blister packing of various syringes, ampoule bottles and medical products.

- Applied to sealed blister packing of food, electronic parts, hardware products, etc.

Feature

- Main drive: main motor located at the back of machine ,easy for maintenance. Synchronous belt drive instead of chain belt drive to reduce oil stain.

- Guide rail installation method: guide rail of the cabinet is installed in cantilever way .It is convenient for the operator to remove the dropped medicine.

- Mould base installation and adjustment: adopt lathe type guide rail and pinion and rack adjustment way. with position indicator and scale ruler for mould position adjustment.

- All moulds including forming mould, heat-sealing mould, batch number emboss printing mould, punching mould can be orientation-guide pushed into its position by hand and mould handle rocked to finish mould change fast with no need wrench or other tools.

- Adopt air shaft to install PVC material and aluminum foil, adopt PVC connection device to change roll material more faster.

- PVC loading adopt roller trace to avoid PVC material being over-stretched during material pulling.